Industry leading

innovations.

innovations.

Leisure Pools is an industry leader with its investments in the best raw materials, ongoing new technology development, and an exceptional quality control manufacturing process that ensures the highest standards possible.

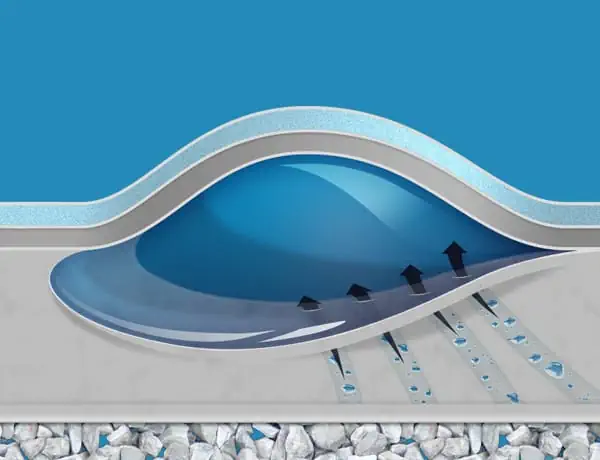

Surrounded in a Core of Strength

Every Leisure Pool comes equipped with our patented Composite Armour™ Core of Strength. This is the highest level of technology in composite swimming pool manufacturing and, to our knowledge, we are the only company that is committed to providing advancements of this calibre.

Strength and durability are intertwined.

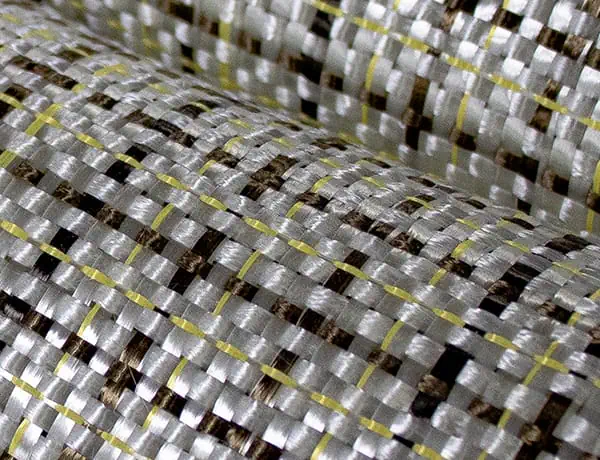

Composite Armour™ is a carefully woven, patented blend of three high performance fibres. Bullet proof vests, body armour, military vehicles, wind turbines and various aerospace, automotive and numerous other cutting edge applications all owe credit to the incredible strengths of these fibres.

A patented blend of 3 really tough fibres.

DuPont™ Kevlar ®

Provides bend strength without stretching or shrinking and incredible resistance to stress and fatigue.

Carbon Fibre

Carbon atoms organised into a crystalline structure produce a strength-to-weight ratio higher than steel and titanium.

Basalt Fibre

Made from volcanic lava rock and offering a naturally superior compression strength with an increased resistance to fracture.

When combined and strategically embedded within Vinyl Ester Resin-reinforced fibreglass, these fibres form a composite matrix of structure and strength, designed to leverage stability against external pressures.

Sure-footed confidence.

From entry steps to benches, spa sides and bottoms, splash pads and even side walls, the integrated features of every Leisure Pool are reinforced with additional Composite Armour™ inserts. The result is a pool that feels incredibly solid under every step.

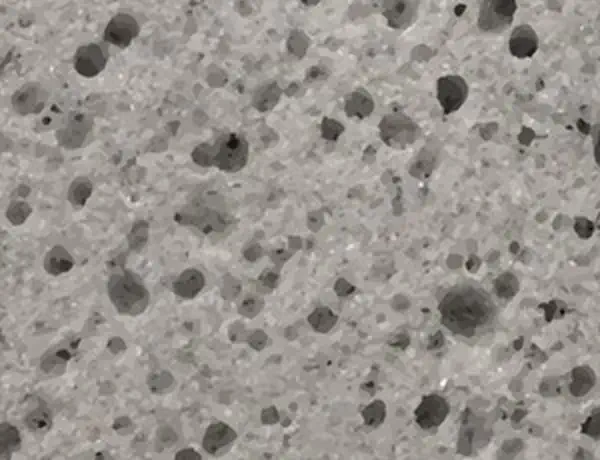

Resin is the most concentrate ingredient in a fibreglass pool shell, compromising almost 70% of the makeup.

Material quality makes a difference.

As a superior alternative to the industry standard polyester resin, Vinyl Ester Resin is less sensitive to ambient conditions, creates a better bond between layers, is less likely to show stress cracking and, most importantly, leaves fewer open cavities within its molecular chain to trap and house water within the laminate.

We only use the best, but others use less.

Some companies include a single layer of Vinyl Ester Resin as a protective barrier, alternating in polyester resin bulk layers to cut manufacturing costs. Unfortunately, this produces a final product that is still susceptible to osmosis. But you may not know it for years.

Leisure Pools use Vinyl Ester Resin throughout the manufacturing process.

Years of show-stopping performance.

First introduced to the Australian market over 20 years ago, AQUAGUARD®X gelcoat provides excellent UV, blister and chemical resistance. It has delivered years of outstanding satisfaction to Leisure Pools customers all across the world, even holding up to the blistering heat of an Australian summer.

Radiant beauty from the inside out.

Leisure Pools continues to import AQUAGUARD®X gelcoat from our partners and suppliers, Allnex, the leading global company for industrial coating resins. This superior product allows the mesmerizing surface of every Leisure Pool to be covered by a 10 Year Gelcoat Warranty.

Not simply a splash of colour.

Designed to shine like a radiant cut diamond.

Watch as light shimmers across your backyard, creating a brilliant outdoor living experience.

Envisioning the mould.

Construction of a Leisure Pool begins with a simple conceptual drawing. Our team of master carpenters then turn this idea into a full-size wooden pool, off which a precise negative mold is cast.

Mutliplying the design.

The mold is then wheeled through various stations of our environment-controlled manufacturing facility, where a team of fibreglass laminators reference benchmarked standards and construct a composite fibreglass pool shell around it.

Hitting the mark.

Quality control measures include batch testing of raw materials for flexural and tensile strength, cure percentages, barcoal hardness, burn and boil limits, and thickness inspections in precise locations on every manufactured shell.

Passing our strict standards.

Confidently constructed with care and pride.

Once the shell is separated from the mold and passes a thorough inspection, it is ready to be delivered to your home for installation.

Lifetime warranties.

Leisure Pools is proud to cover every one of our composite fibreglass swimming pool shells with a Lifetime Structural Warranty and Lifetime Structural Osmosis Warranty.

Our confidence to do so is built on the investment of technological advancements like Composite Armour™ and Composite Armour™ Step Technology, and is supported by a commitment to using the highest quality raw materials throughout our cutting-edge manufacturing process.

We understand that your outdoor living experience is a substantial investment.

You want to make the right decision. You want to know that the company you are working with will stand behind their product.

We want you to have peace of mind and enjoy your pool for years to come.

We offer the Leisure Pools Lifetime Warranties to you as a seal of commitment to the quality of our product. This is our promise to you.